Get To Know About Castable Refractories!

Loka Refractories - Are you familiar with castable refractory? If not, you're in luck because this article will add to your knowledge about this material.

As discussed in the article Monolithic Refractory: Definition, Strengths, and Types, castable is a monolithic refractory that mixes raw materials and chemical binder using water and then forms it using a mold/cast.

Chemical binders that are often used are high alumina castable (HAC), hydratable alumina, and colloidal silica. Adding a chemical binder will form a ceramic bond after heating. Castable, which is also commonly called concrete refractory, is commonly used to coat furnaces, kilns, and so on.

Alumina and alumina silicate castables have been registered as SNI (Indonesian National Standard) products with SNI number 15-0809-2001. The two types of castable are classified as follows.

Classification of Alumina and Silicate Alumina Castable

1. Regular Castable

Regular castable has a hydraulic cement and CaO content of less than 2.5%. There are two types of regular castable based on MOR (Modulus of Rupture), namely normal type (MOR ≥ 300 psi) and high strength type (MOR ≥ 600 psi). Permanent linear shrinkage should not exceed 1.5% at fuel temperature.

2. Low Cement Castable

Castable with CaO content between 1-2.5%.

3. Ultra Low Cement Castable

Castable which has a CaO content of between 0.2-1%.

4. No Cement Castable

Castable which has a CaO content of less than 0.2% and comes from aggregates.

5. Insulating Castable

Insulating castable has the main function of producing thermal insulation. This type of castable has low density, low thermal conductivity, and has lower mechanical strength than ordinary castable. Permanent linear shrinkage should not be more than 1.5% at fuel temperature.

In addition, there are types of castable which are grouped based on the bonding process as follows.

Types of Castables based on Bonding Process

- Castables that harden at dry temperatures

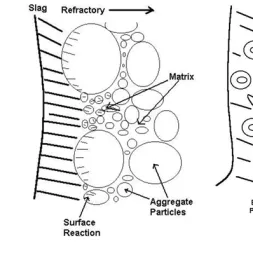

Strong bonds and dense materials will be formed from the reaction of refractory grains with matrix materials in aqueous media. The matrix in question is refractory cement and phosphate.

- Castable which hardens at high temperatures

A strong bond is formed between the refractory grains and the matrix in the form of ceramic bond (clay) so that hardening occurs at relatively high temperatures.

Source: - Gupta, O.P. 2018. Elements of Chemical Process Technology. New Delhi: Khanna Book Publishing.