Monolithic Refractory: Definition, Strengths, and Types

Loka Refractories - Based on their shape, refractory materials are classified into shaped/brick refractory, unshaped/monolithic refractory, and fibrous material.

A brief explanation of the classification has been presented in a previous article entitled Refractory Classification: What Are Refractory Shapes?. In this article, we will focus on the explanation of monolithic refractories.

Want to add more insight of monolithic refractories? Check out the explanation from the definition to the type of product.

What is Monolithic Refractory?

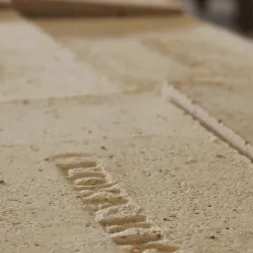

Monolithic refractory, is a heat and flame resistant material that does not go through the process of forming by a press machine as well as burning before it reaches the consumer.

That's what makes this material do not have a definite shape, meaning that monolithic refractory can be formed or casted as desired when applied.

The Strengths of Monolithic Refractory over Shaped Refractory

One of the other forms of refractory is shaped refractory as opposed to monolithic, it has a definite shape. Compared to shaped, monolithic has several strengths including:

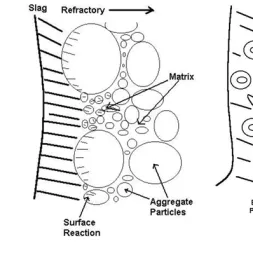

1. The absence of a regular connection is the weak point of shaped refractory products;

2. Faster to use and easier to handle and transport;

3. Better coverage to reduce downtime during maintenance;

4. Saving storage space because it does not have a definite shape;

5. More heat efficient;

6. More resistant to spalling or corrosion;

7. Has greater volume stability.

Application of Monolithic Refractory

Application of monolithic refractories are done by spraying, ramming, casting, or molding. This type of refractory is generally applied to fill gaps and adhesive refractory stones and linings.

Types of Monolithic Refractories

1. Castable

Castable is a type of refractory that mixes raw materials and chemical binder using water and then forms it using a mold/cast. Chemical binders that are often used are high alumina castable (HAC), hydratable alumina, and colloidal silica.

Adding a chemical binder will form a ceramic bond after heating. Another form of castable is Insulating castable which has the main function of producing thermal insulation. This type of castable has low density, low thermal conductivity, and has lower mechanical strength than ordinary castable.

2. Plastic Refractories

Plastic, is a monolithic refractory which is applied using a rammer without the need to prepare it first. Plastic refractories are distributed wrapped in polyethylene in a hard condition and form blocks.

3. Ramming mix

Ramming mix, which is a granular refractory which is strengthened by a ceramic bond arrangement after being heated. This material is similar to plastic refractory but harder. Just like plastic refractory, ramming mix is applied using a pneumatic rammer.

4. Mortar

Mortar is a material used as the adhesive of refractory bricks in a refractory lining. Initially, mortar did not include shaped nor unshaped refractory. There are three types of mortar, namely heat-setting, air-setting, and hydraulic setting.

5. Gunning

Gunning mix, which is a monolithic refractory material which is applied by spraying it on the surface or wall using various tools in the form of an air placement gun.

6. Slinger mix

Slinger mix, namely material that is applied using a slinger machine.

7. Patching and Coating Materials

This material has properties similar to mortar, but the grain size is more controlled making it suitable for patching and coating.

8. Light-weight castables

Refractory material produced by mixing hydraulic cement, a light and porous raw material, and water. Light-weight castables are molded and applied to the lining of furnaces, kilns, and so on.

Source:

- The Technical Association of Refractories, Japan. 1998. Refractories Handbook. Tokyo: The Technical Association of Refractories, Japan.

- Gupta, O.P. 2018. Elements of Chemical Process Technology. New Delhi: Khanna Book Publishing.