Need Fire Clay Brick and High Alumina Brick Refractories? Here's Some Info For You!

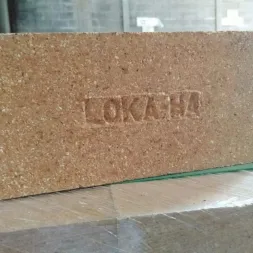

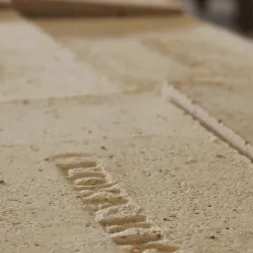

Loka Refractories - Brick is a refractory material that is very commonly found and used.

Based on its shape, Brick refractory is classified into shaped refractory, because it is through a molding process using a press machine so that it has a definite shape.

Like refractory materials in general, brick refractories are also classified into several types, you know!

One of the most commonly used types of refractory bricks is alumina silicate brick (fire clay brick) and high alumina bricks.

Fire clay brick and high alumina brick? What kind of refractory is that?

Fire clay bricks and high alumina bricks have various combinations of alumina and silica content. They range from almost 100% alumina with a little silica, to almost 100% silica with a little alumina.

In addition, the material also has several features including:

-High resistance to thermal shock, abrasion and chemical;

-Easy and wide application;

-Low cost;

-etc.

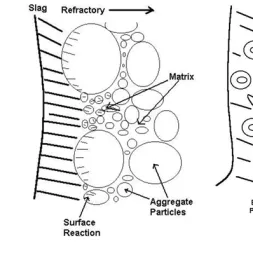

Refractory stone is commonly used in lining furnaces, kilns, incinerators, and the like. Each stone is glued together using a refractory cement mortar with similar specifications.

Classification of fire clay brick and high alumina brick

Eits, not quite up there! Fire clay bricks are also classified based on physical properties including: Super-duty, High-duty, Semi-silica, Medium-duty, and Low-duty.

Meanwhile, high alumina bricks are classified based on their alumina content, from 50% to 99%.

Does Loka Refractories produce fire clay bricks and high alumina bricks?

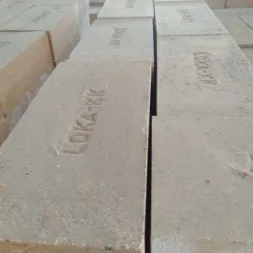

Of course! we produce fire clay bricks (SK-32, SK-34, SK-36) and high alumina bricks (SK-38) with a standard size of 230x114x65 mm.

We also provide arch, wedge, and key types. You can also order according to your needs!

Just send the drawings/specifications needed to:

E-mail : info@lokarefractories.com

Phone : 031-7663307

Whatsapp : 0821-4280-8500

Based on its shape, Brick refractory is classified into shaped refractory, because it is through a molding process using a press machine so that it has a definite shape.

Like refractory materials in general, brick refractories are also classified into several types, you know!

One of the most commonly used types of refractory bricks is alumina silicate brick (fire clay brick) and high alumina bricks.

Fire clay brick and high alumina brick? What kind of refractory is that?

Fire clay bricks and high alumina bricks have various combinations of alumina and silica content. They range from almost 100% alumina with a little silica, to almost 100% silica with a little alumina.

In addition, the material also has several features including:

-High resistance to thermal shock, abrasion and chemical;

-Easy and wide application;

-Low cost;

-etc.

Refractory stone is commonly used in lining furnaces, kilns, incinerators, and the like. Each stone is glued together using a refractory cement mortar with similar specifications.

Classification of fire clay brick and high alumina brick

Eits, not quite up there! Fire clay bricks are also classified based on physical properties including: Super-duty, High-duty, Semi-silica, Medium-duty, and Low-duty.

Meanwhile, high alumina bricks are classified based on their alumina content, from 50% to 99%.

Does Loka Refractories produce fire clay bricks and high alumina bricks?

Of course! we produce fire clay bricks (SK-32, SK-34, SK-36) and high alumina bricks (SK-38) with a standard size of 230x114x65 mm.

We also provide arch, wedge, and key types. You can also order according to your needs!

Just send the drawings/specifications needed to:

E-mail : info@lokarefractories.com

Phone : 031-7663307

Whatsapp : 0821-4280-8500

Latest Article